Committed to innovation and sustainable development

Since 2009, we have become a first tier material supplier of China National Petroleum Corporation (CNPC) and have been using CNPC’s energy-saving technology The WCYJD series vertical pumping unit for central testing is 26-40% more energy-efficient than the “beam pumping unit”.

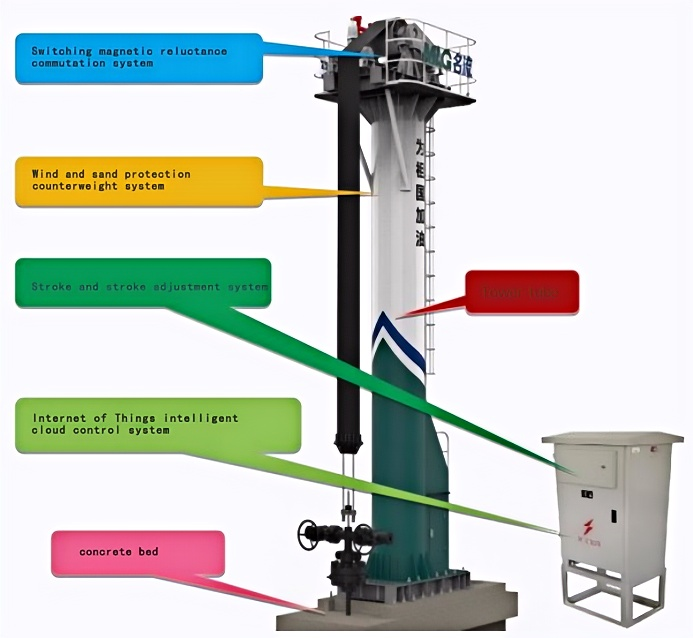

(1) Vertical tower oil pumping unit

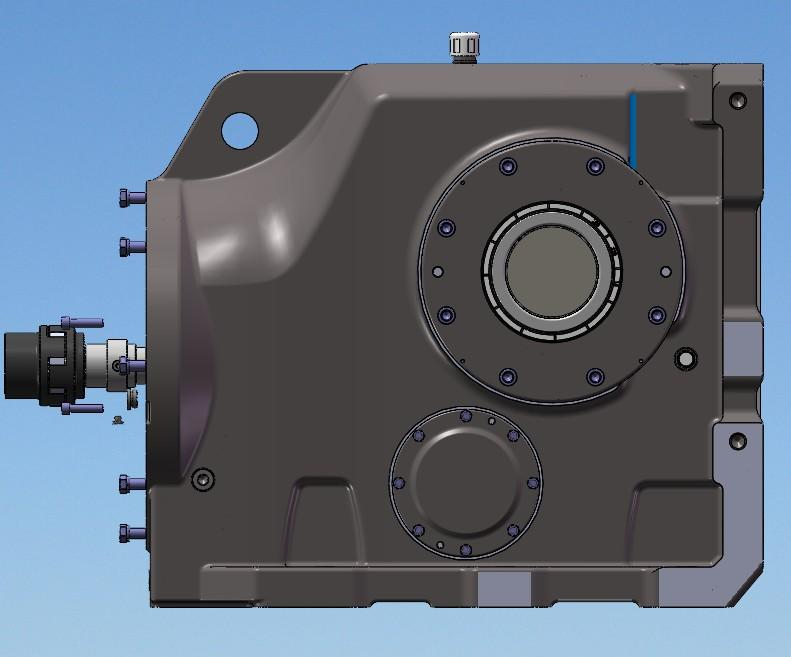

Vertical tower oil pumping unit- -structure display diagram.

Four systems:

1.Switching magnetic reluctance commutation system.

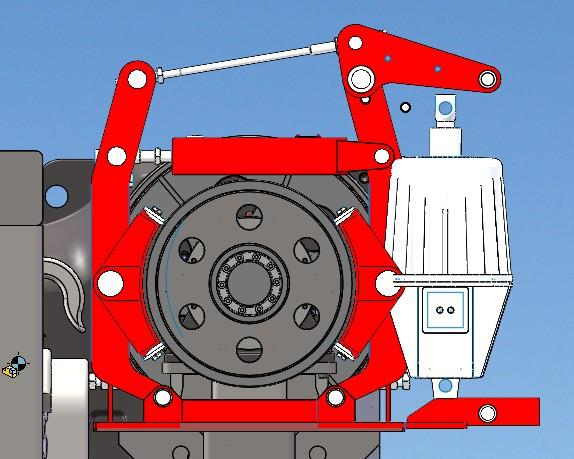

2.Stroke and stroke adjustment system.

3.Wind and sand protection counterweight system.

4.Internet of Things intelligent cloud control system.

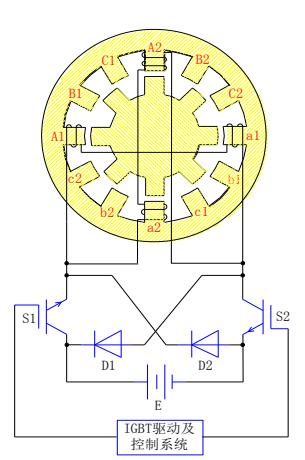

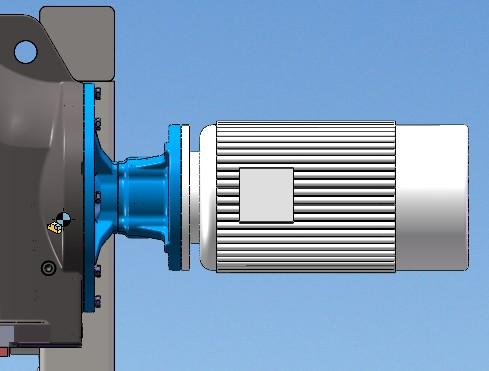

Vertical tower oil pump machine-switch magnetic resistance reversing system

Switch resistance motor is a stator, rotor double convex pole variable resistance motor. The motor shown in the figure is 12 / 8 pole structure, the stator is 12 poles, the radial opposite 4 poles form a phase, and the rotor is 8 poles. The stator and rotor are made of silicon steel sheet stack. There is neither winding nor permanent magnet on the rotor, and there is a concentrated winding on the stator pole. This particular combination form has been widely used, especially suitable for those Wells that require heavy load and obvious load changes.

◆ The starting torque is large, the starting current is small, the energy saving effect is very obvious, efficient energy saving 26-40%. Power factor is above 0.95, and no power compensation is required.

◆ Because the rotor of the switch resistance motor has no winding and mouse cage strip, the motor can run at high speed without deformation. The stator coil is easy to insert, short and firm end, most of the heat consumption is in the stator, easy to cool, high temperature resistance, suitable for field harsh working environment, long-term reliable operation.

◆ Adopt advanced controller system, with overload, overvoltage and other comprehensive protection, in the phase absence or overload can operate, the impulse will only drop, will not burn the motor and controller.

switch magnetic resistance reversing system

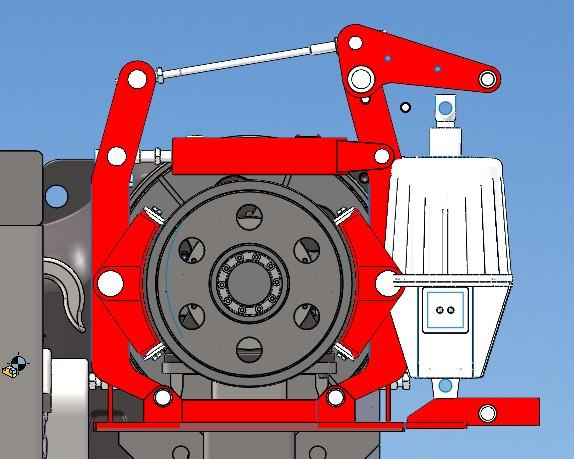

Vertical tower pumping unit

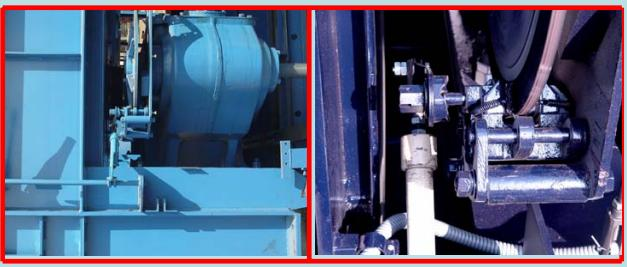

stroke stroke adjustment system、Sand-proof counterweight system。

Stroke stroke adjustment system

- Stroke, stroke times are directly given through the touch screen number. Simple operation, display and intuitive to meet the operating conditions of each oil well.

- The upper and lower strokes can be adjusted respectively, which is conducive to the filling of the pumping pump and improve the oil recovery efficiency.

- The optimized combination of long stroke and low stroke not only ensures the requirements of oil production volume, but also helps to extend the service cycle of the oil pump and improve the system efficiency.

Sand-proof counterweight system

- The counterweight system is located in the tower cylinder, which can effectively resist the influence of the harsh natural environment on the counterweight.

- Using the principle of Libra structure, its advantages of reasonable structure, reliable operation, clever design, simple installation.

- Adopt no guide wheel design, without maintenance and maintenance, effectively ensure the safety of people and livestock and the normal operation of equipment, prevent major accidents, and improve the safety level of equipment.

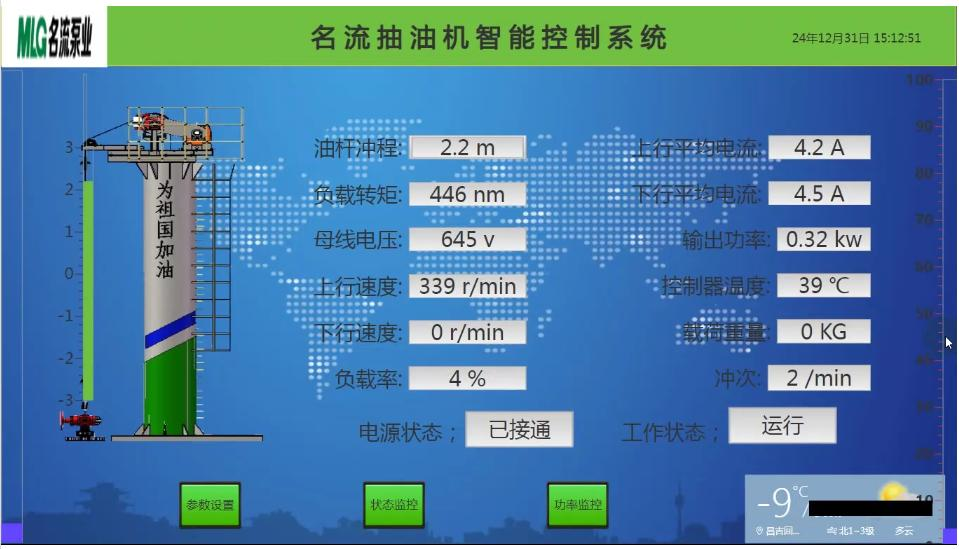

Internet of Things interconnection, intelligent cloud control system

◆ Remote monitoring of the voltage, current, frequency, power, stroke, stroke, motor temperature rise, torque, current position and other parameters of the pumping unit, with intuitive display.

◆ Remote start and shut down the oil pump.

◆ Pumator fault, voltage phase deficiency, pressure is too high, the temperature is too high, automatic alarm.

◆ It can realize automatic shutdown of abnormal parameters, opening and closing detection of control box door.

◆ Supports remote setting of working parameters and lower limit alarm values of the pumping unit monitoring terminal.

◆ Automate to generate the operating parameter trend analysis curve of the oil production machine.

Vertical tower oil pump machine- -product specification parameters

| model | outline dimension (m) | outline dimension (m) | Motor Rrating (kW) | travel (m) | Rush time (times / min) |

| WCYJD6-6-10Z | 2.3*2.0*6 | 6 | 10 | 6 | 5 |

| WCYJD8-6-20Z | 2.3*2.0*6 | 8 | 18.5 | 6 | 4 |

| WCYJD10-6-30Z | 2.5*2.0*8 | 10 | 22 | 6 | 4 |

| WCYJD12-6-40Z | 2.5*2.6*12 | 12 | 22 | 6 | 4 |

| WCYJD14-7-40Z | 2.8*2.6*12 | 14 | 40 | 7 | 4 |

| WCYJD16-8-40Z | 2.8*2.6*12 | 16 | 45 | 8 | 4 |

| WCYJD18-9-40Z | 2.8*2.6*12 | 18 | 55 | 9 | 4 |

| WCYJD20-8-40Z | 3.0*2.6*13 | 20 | 75 | 8 | 3 |

| WCYJD22-8-40Z | 3.0*2.6*13 | 22 | 90 | 8 | 3 |

(2) Comparison of technical advantages

Introduction to technical advantages

Five core technologies of WCYJD series pumping unit:

- Low current and high torque, high efficiency and energy saving 26~40%;

- given stroke number, cascade adjustment;

- built-in counterweight, power brake, safe and reliable;

- accurate mechanical design of gravity and counterweight, simple movement;

- online monitoring, Internet connection, and intelligent cloud control.

Compared with the conventional vertical pumping unit, the comparative advantages

◆ The reversing system adopts switching resistance motor reversing, can be frequent positive and reverse direction, mechanical strength and reliability are higher than other types of motor, the failure rate is very low, without maintenance and maintenance.

◆ High efficiency, obvious energy saving, small starting current, large torque, high power factor, no pollution to the power grid, no need for reactive power compensation, suitable for harsh working environment in the field. Other cage type AC asynchronous motors have low power efficiency and need to do power compensation, easy to be fined by the power bureau.

◆ The stroke number is given and convenient to improve the oil recovery efficiency; other conventional pumping units need to move the machine, adjust, time-consuming and laborious.

◆ The counterweight is located in the tower cylinder, which can effectively resist the influence of wind power on the counterweight, and effectively ensure the safety of people, livestock and equipment. Other conventional pumping units are exposed, there are safety risks, prone to major accidents.

◆ Operation and maintenance is convenient to move, using hydraulic shift machine, 2-3 hours to complete the operation, smooth and smooth operation. Other conventional pumping units are difficult to move the machine, need to use the crane and other assistance, spend a lot of time and manpower and material resources.

Compared with the conventional vertical pumping unit, the comparative advantages

Conventional oil pumping machine

Conventional oil pumping machine

Complex mechanical structure, high maintenance cost, low efficiency, and high environmental requirements.

Celebrity series pumping machine

Celebrity series pumping machine

Simple structure, high efficiency and reliability, adaptation, strong environment, easy to achieve automatic control, energy saving and environmental protection.

Conventional oil pumping machine

Conventional oil pumping machine

Belt drive has limited service life, poor transmission efficiency, stability, needs regular adjustment, environmental requirements and high maintenance cost.

Celebrity series pumping machine

Celebrity series pumping machine

Simple structure, compact, improve the operation efficiency and stability of the equipment, and reduce the maintenance cost.

Conventional oil pumping machine

Conventional oil pumping machine

Brake manual operation, poor safety, low efficiency, the reliability problem is uncertain.

Celebrity series pumping machine

Celebrity series pumping machine

Pumping machine automatic brake system, safe and reliable, quick brake response speed, convenient management and control.

Conventional oil pumping machine

Conventional oil pumping machine

Ununiform lubrication, the influence of external sand is easy to make lubricating oil pollution, increase the maintenance cost.

Celebrity series pumping machine

Celebrity series pumping machine

Good lubricity, high and low temperature resistance, leakage prevention, sex, improve the operation efficiency and reliability of the equipment, reduce the maintenance cost.

- Market application cases

- FAQ

- Future development trend